Pb-Sn | LEAD-TIN | BINARY EUTECTIC PHASE DIAGRAM : PARTLY SOLUBLE IN SOLID STATE#materialscience - YouTube

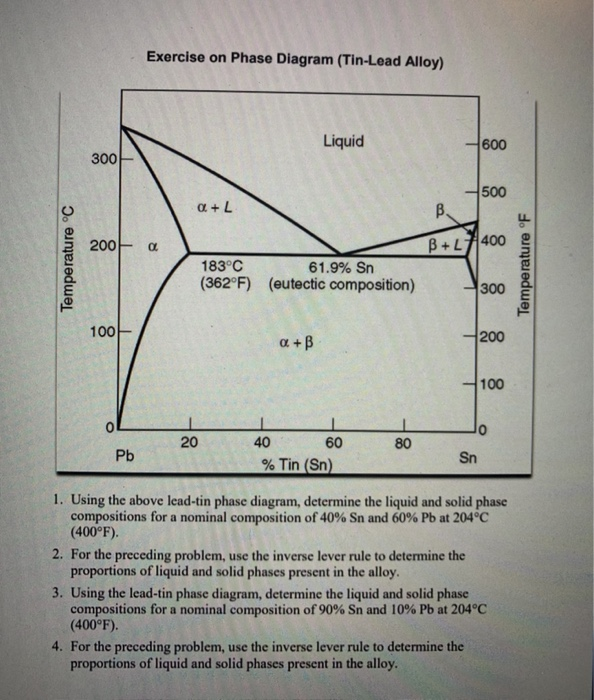

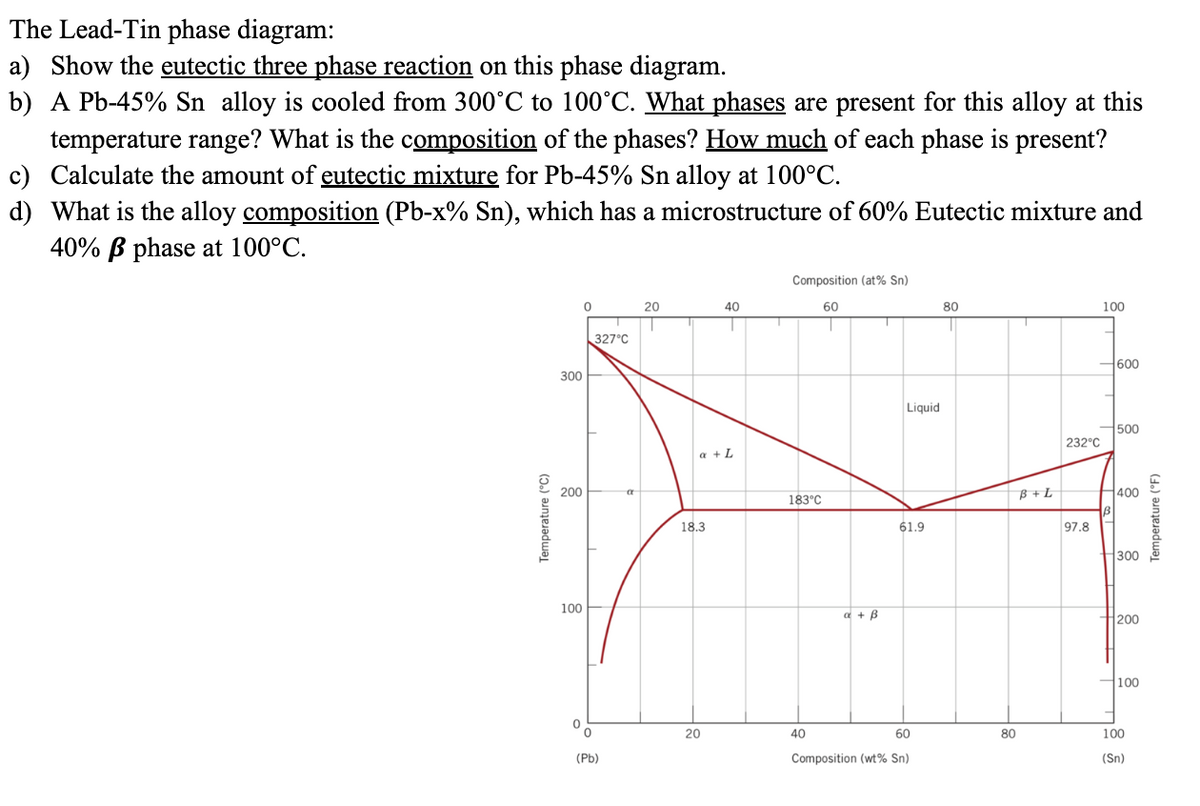

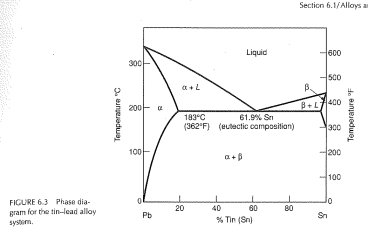

A lead-tin alloy of composition 90 wt% Sn-10 wt% Pb is slowly heated from a temperature of 110 degrees C. (a) At what temperature does the first liquid phase form? (b) What

Solved) - Using the lead—tin phase diagram in Figure 6.3, de-termine the... - (1 Answer) | Transtutors

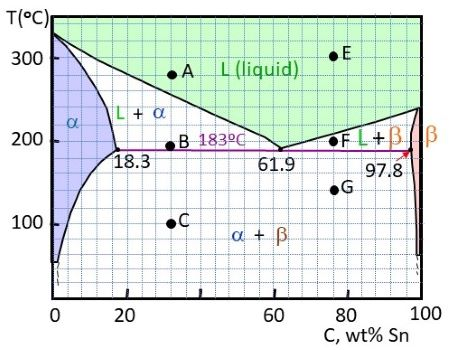

The lead-tin phase diagram is shown below. Using this diagram determine which of the following phases/phase combinations will be present for an alloy of composition 79 wt% Sn - 21 wt% Pb

A) Calculated lead-tin phase diagram and DSC curve of their eutectic... | Download Scientific Diagram

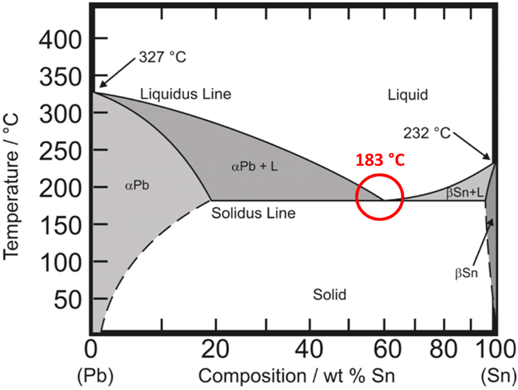

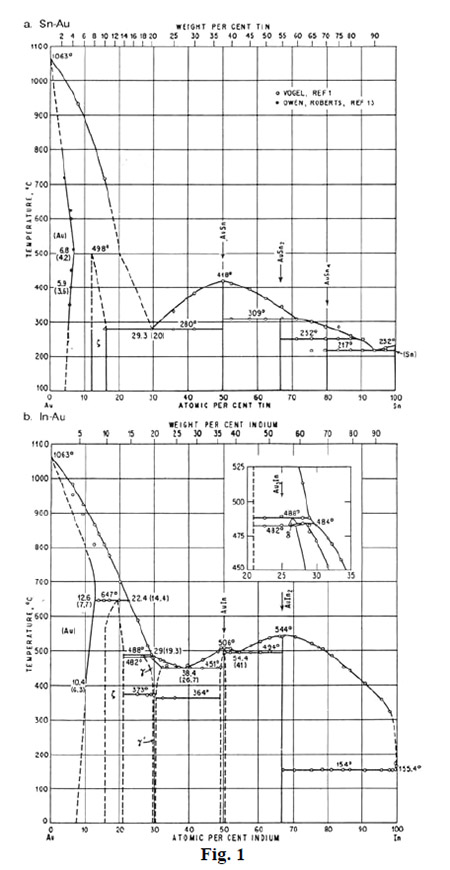

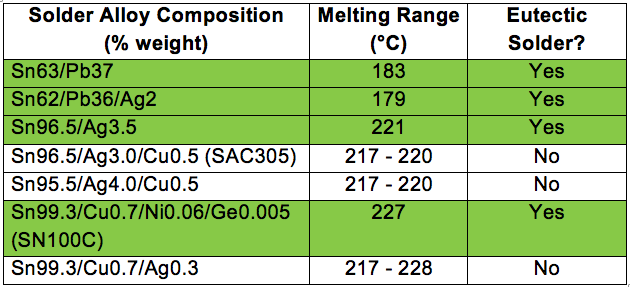

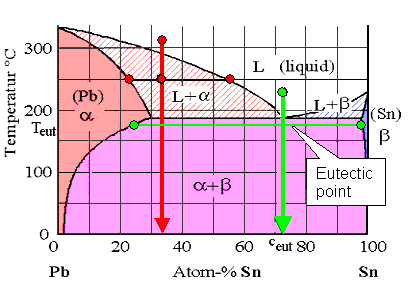

Tm (Sn) = 232 C, Tm (Pb) = 327 C but Tm(Sn0.62Pb0.38) = 183 C, so this is a common soldering alloy. Tm (Au) = 1064 C, Tm (Si) =

Changing the Composition of Your Tin-Lead Solder Pot | Adam Murling | Indium Corporation Blogs | Indium | Indium Alloy | Indium Corporation | Lead Free Solder | No Clean Solder

Pb-Sn | LEAD-TIN | BINARY EUTECTIC PHASE DIAGRAM : PARTLY SOLUBLE IN SOLID STATE#materialscience - YouTube